In today’s highly competitive manufacturing landscape, precision machining San Diego has become an indispensable process for creating high-quality parts across various industries. Whether it’s for aerospace, automotive, medical devices, or consumer products, precision machining ensures that every component is crafted to exact specifications. But what exactly is precision machining, and why is it so important? In this article, we’ll dive into the basics of precision machining, explain its benefits, and explore how CNC machining plays a pivotal role in producing CNC machined parts that meet the most stringent standards.

What Is Precision Machining? A Quick Overview

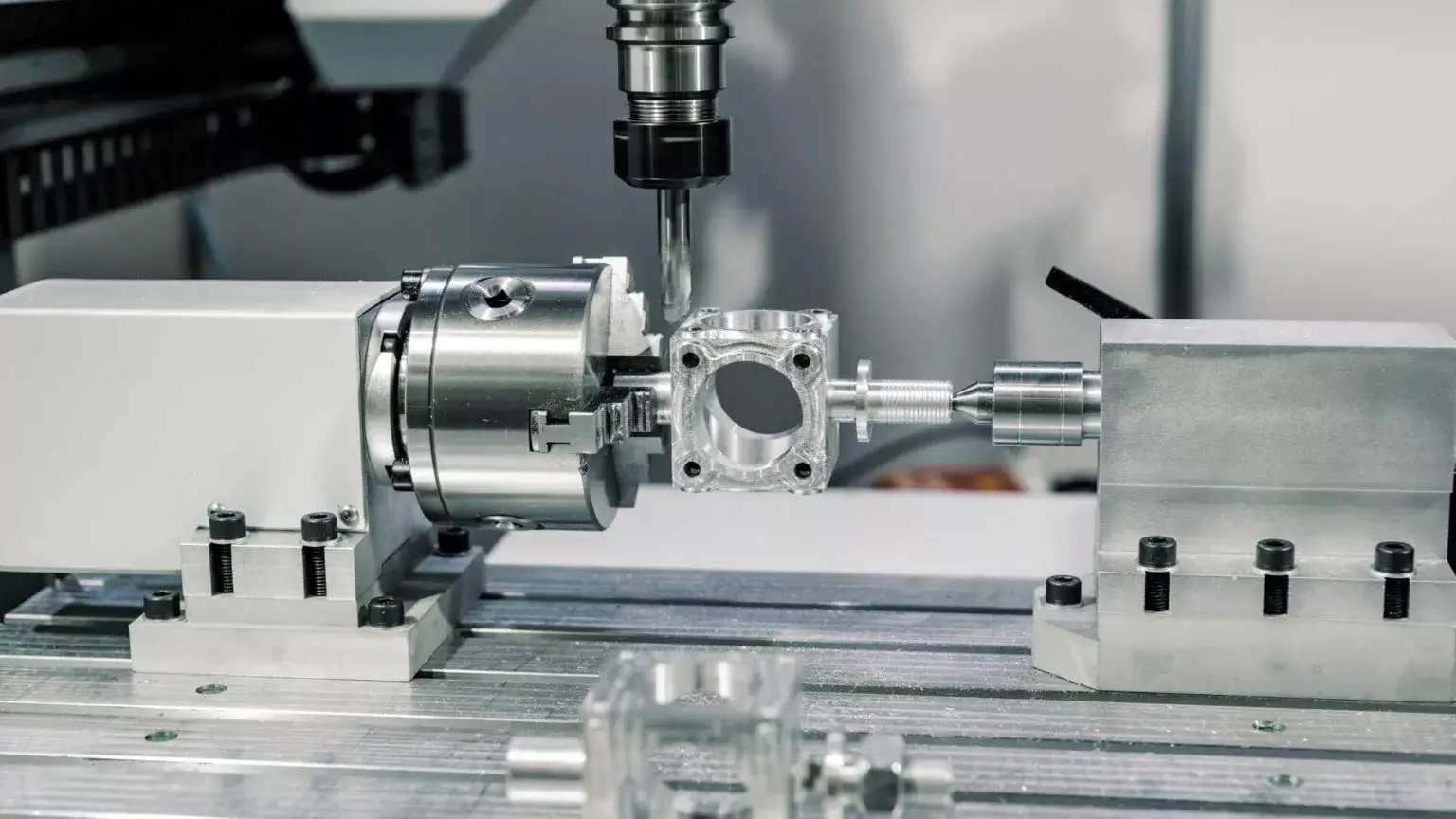

Precision machining is a manufacturing process that involves the careful removal of material from a workpiece to achieve highly accurate dimensions, tight tolerances, and smooth finishes. This process is essential for producing CNC machined parts that require a high level of detail and consistency.

Unlike traditional machining, where operators manually control the machine tools, CNC machining (Computer Numerical Control machining) uses computer programs to control the machinery. This automation leads to faster, more consistent, and highly precise manufacturing outcomes.

How Does Precision Machining Work?

Understanding how precision machining works can help you appreciate its complexity and why it’s so critical in modern manufacturing.

1. Design and Blueprinting

The first step in precision machining is creating a detailed design of the part using CAD (Computer-Aided Design) software. These blueprints are then used to program the CNC machining process.

• CAD Files: The design is translated into a set of instructions (G-code), which guides the CNC machine on how to shape the material accurately.

• Material Selection: The choice of material is crucial, as it must be compatible with the machining process and the requirements of the final part.

2. CNC Machining Process

Once the program is ready, the machining shop loads the material (often a metal or plastic) into the CNC machine, which will perform operations like turning, milling, drilling, or grinding to shape the material.

• Multi-Axis Machining: Modern CNC machines use multiple axes (usually 3 to 5) to move tools and the workpiece, enabling the machine to cut, shape, and drill from various angles.

• High Precision: The CNC machine follows the program’s instructions to remove material in precise increments, achieving tight tolerances (as small as 0.001 inches).

3. Finishing Touches

After the initial machining steps are complete, the part may go through additional processes such as polishing, coating, or heat treatment to achieve the desired final finish.

• Surface Finishing: To meet aesthetic or functional requirements, parts may undergo polishing or coating to improve appearance or prevent corrosion.

• Quality Control: Every part is checked for accuracy and quality through inspections using precision measurement tools like micrometers and CMM (Coordinate Measuring Machines).

Why Is Precision Machining So Important?

With the increasing demand for high-performance and reliable parts, precision machining is essential to ensure that components are manufactured to meet strict specifications. Here’s why it’s so important:

1. Achieving Tight Tolerances

One of the key advantages of precision machining is its ability to achieve tight tolerances. Whether it’s aerospace components or medical devices, even the smallest deviations in part dimensions can lead to failure or malfunction.

• Critical Industries: Industries like aerospace, automotive, and medical devices rely on parts that must function flawlessly under extreme conditions.

• Reliability: CNC machined parts produced through precision machining are designed to be reliable and durable, ensuring that the product functions as intended.

2. Complex Designs Made Possible

Another significant benefit of precision machining is its ability to create complex geometries that would be challenging or impossible to achieve using manual methods.

• 3D Designs: With CNC machining, manufacturers can produce parts with intricate designs, curves, and holes, all with a high degree of precision.

• Multiaxis Operations: Advanced CNC machining equipment allows for multiple axes of operation, making it possible to work with complex 3D shapes in a single setup.

3. Consistency and Reproducibility

Once a program has been developed and tested, CNC machines can consistently replicate the same process across multiple parts, ensuring that each part meets the exact specifications.

• No Human Error: Unlike manual processes, which are prone to human error, CNC machining is automated, reducing the risk of mistakes and enhancing consistency.

• Repeatability: The ability to produce the same part thousands of times without variation is crucial for industries that need large quantities of parts.

The Role of CNC Machining in Precision Manufacturing

CNC machining has significantly transformed the field of precision machining, enabling manufacturers to create high-quality parts with greater speed, accuracy, and flexibility. Here’s how CNC machining contributes to the precision machining process:

1. High-Speed Production

CNC machines can operate continuously, running 24/7 with minimal downtime. This allows manufacturers to achieve high production rates without sacrificing quality.

• Increased Productivity: CNC machines can produce parts much faster than traditional manual methods, cutting down production time and costs.

• Automation: With minimal human intervention required, CNC machining reduces labor costs while maintaining high output levels.

2. Flexibility and Customization

CNC machines are highly flexible, capable of producing both large volumes of the same part and custom, one-off designs. Whether you need a prototype or a high-volume production run, CNC machining can handle both with ease.

• Quick Adjustments: Modifying a program to produce a new part design is a straightforward task, which makes CNC machining ideal for industries that require frequent design changes.

• Customization: Complex, bespoke parts can be produced without needing to create a completely new tool or mold, saving both time and cost.

3. Precision and Detail in CNC Machined Parts

The use of CNC machining in precision manufacturing ensures that each CNC machined part is created with exacting standards. From intricate components to large industrial parts, CNC machined parts are made to meet tight specifications and rigorous quality standards.

• Precise Measurements: CNC machines can execute cuts and drills with accuracy down to thousandths of an inch, ensuring each part is identical to the next.

• Superior Surface Finishing: CNC machines also allow for smooth surface finishes that are essential for both aesthetic and functional purposes.

Key Industries Benefiting from Precision Machining

Precision machining and CNC machining play a pivotal role across many industries, each requiring highly specialized parts. Here are some industries that benefit from precision machining:

1. Aerospace and Aviation

The aerospace industry demands parts that meet extremely tight tolerances and can withstand high pressures and temperatures. Precision machining ensures the creation of components such as turbine blades, engine parts, and airframes.

2. Medical and Healthcare

Medical devices, surgical instruments, and implants need to be manufactured with the utmost precision to ensure they function properly and are safe to use. CNC machined parts for the medical industry include prosthetics, catheters, and diagnostic equipment components.

3. Automotive

The automotive industry benefits from precision machining in the creation of engine components, transmission parts, and even custom high-performance parts for motorsports.

4. Electronics

In the electronics sector, precision machining ensures that small components like connectors, housings, and circuit boards meet the required standards of quality and functionality.

Conclusion

In conclusion, precision machining is a critical component of modern manufacturing, offering unparalleled accuracy, versatility, and reliability in producing high-quality parts. Whether you’re using CNC machining for complex prototypes or high-volume production runs, cnc machined parts San Diego deliver the precision and performance needed in today’s competitive industries.

By choosing a skilled machining shop that specializes in precision machining, businesses can ensure they produce parts that meet exact specifications, perform reliably, and maintain the highest quality standards. In an era where precision and quality are non-negotiable, understanding the basics of precision machining will empower you to make informed decisions and optimize your manufacturing processes.

If you’re ready to take your manufacturing process to the next level, embracing precision machining will ensure you stay ahead in a constantly evolving industry.