Measuring the tiniest movements or distances is critical in science, technology, and manufacturing. This is where the laser interferometer comes in. This instrument uses beams of light to achieve a level of precision that traditional tools cannot match. As industries demand ever greater accuracy, many professionals are exploring the potential of the laser interferometer for industry to improve production, research, and quality control.

The principle behind a laser interferometer may sound complex, but the idea is surprisingly straightforward. Light waves, when split and recombined, create interference patterns that can reveal incredibly small differences in distance or movement. This ability makes it indispensable for engineers, scientists, and technicians alike.

How a Laser Interferometer Works

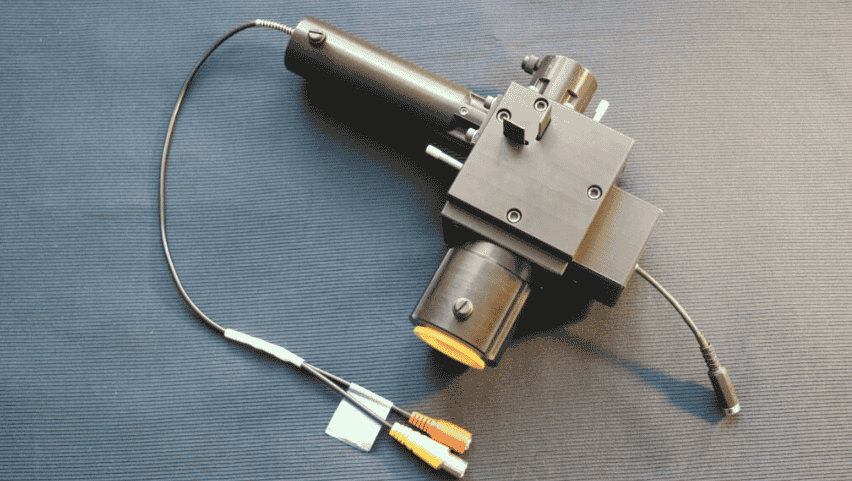

A laser interferometer starts by emitting a stable, single-color laser beam. This beam is divided into two paths using optical components such as mirrors and beam splitters. One path remains fixed as a reference, while the other interacts with the object or surface being measured. When the beams are brought back together, the resulting interference pattern shows even the smallest changes between the two paths.

By analyzing these patterns, users can measure distances or movements down to fractions of a wavelength of light. Because lasers produce a coherent and stable beam, they enhance the accuracy of the instrument, making it far superior to older types of interferometers.

In a factory setting, the laser interferometer for industry might be installed alongside machinery to track motion or verify alignment during production. In a research lab, it could be used to study how materials behave under stress or to calibrate delicate instruments.

Applications of the Laser Interferometer

The laser interferometer is not limited to one field. In engineering, it ensures the precision of machine parts. In optics, it checks the flatness and smoothness of surfaces. In the semiconductor sector, it measures wafer thickness and alignment.

Because of its versatility, the laser interferometer for industry has become a cornerstone in many manufacturing environments. It helps maintain high-quality standards, minimize defects, and improve efficiency by providing real-time, highly accurate data about equipment and processes.

Advantages of Using a Laser Interferometer

Working with a laser interferometer offers several key advantages over traditional measuring instruments:

-

Extremely high precision capable of detecting sub-microscopic changes.

-

Non-contact measurement, which is crucial for delicate or sensitive materials.

-

Flexibility to be used in laboratories, workshops, or directly in production lines.

These benefits explain why the laser interferometer for industry is gaining so much attention worldwide. By investing in such tools, organizations can ensure they stay ahead of competitors in both innovation and quality.

Tips for Getting the Most Out of a Laser Interferometer

To maximize the potential of your instrument, consider the following tips:

-

Maintain a clean environment for the optical components to prevent dust or smudges from interfering with the laser beam.

-

Minimize vibration and air currents in the measurement area, as these can affect readings.

-

Calibrate the system regularly according to manufacturer guidelines to keep measurements consistent.

Following these tips helps keep a laser interferometer in peak condition, ensuring long-term reliability and accuracy.

Why the Laser Interferometer for Industry Is Transforming Production

Factories today operate at extremely tight tolerances. Even a small misalignment or error can result in costly defects. By integrating the laser interferometer for industry into production processes, manufacturers gain the ability to monitor precision in real time.

This real-time feedback means adjustments can be made instantly, reducing waste and increasing productivity. It also supports automation, as machines can be calibrated and monitored continuously without interrupting the workflow.

In this way, the laser interferometer for industry does more than just measure – it helps shape smarter, more efficient manufacturing environments.

Future Trends in Laser Interferometry

As technology advances, laser interferometers are becoming smaller, faster, and easier to use. New designs integrate computer software for automated data collection and analysis, allowing even non-specialists to operate complex systems.

Other innovations focus on environmental resilience, enabling these instruments to deliver accurate measurements despite vibrations, temperature changes, or air fluctuations. Such developments will make the laser interferometer even more valuable to both scientists and industrial professionals in the coming years.

How Laser Interferometers Impact Everyday Life

Though most people never see a laser interferometer, its impact is everywhere. The precision it provides helps ensure the safety of cars, the reliability of medical devices, the performance of smartphones, and the quality of aerospace components.

By enabling higher standards across industries, these instruments quietly improve the products and technologies we use every day. The laser interferometer for industry thus supports progress that touches virtually every aspect of modern life.

Conclusion

The laser interferometer is a powerful tool that turns light’s interference into highly accurate measurements. Its ability to detect incredibly small changes makes it indispensable in fields ranging from research to industrial production.

By understanding how a laser interferometer works, its benefits, and the growing role of the laser interferometer for industry, professionals can make informed decisions about integrating this technology into their work. Whether you’re a scientist seeking precision or a manufacturer striving for quality, this instrument offers a path to greater accuracy and efficiency.

FAQs

Q1: What is a laser interferometer used for?

It is used to measure extremely small distances, movements, or surface variations with extraordinary precision in research and industrial settings.

Q2: How does a laser interferometer improve accuracy?

It uses the interference of laser light beams, which allows detection of changes at the sub-microscopic level far beyond traditional tools.

Q3: Why is the laser interferometer for industry important?

It helps manufacturers monitor and maintain precision in real time, reducing defects and improving production efficiency.

Q4: Can a laser interferometer be used outside of laboratories?

Yes, many modern models are designed for industrial environments, making them suitable for factories, workshops, and field applications.