Luxury wrapped rigid cardboard boxes are becoming increasingly popular for a variety of reasons. First and foremost, they’re beautiful. With their sleek designs and luxurious materials, these boxes are perfect for any product that needs to look high end. But what’s even more impressive is the machinery that’s required to produce them.

In this blog post, we’ll explore the different types of machinery that are needed to produce these boxes and the benefits that they offer. From speed to accuracy, read on to learn about all the advantages of using machinery for luxury wrapped rigid cardboard boxes.

What Is Machinery For Rigid Cardboard Boxes?

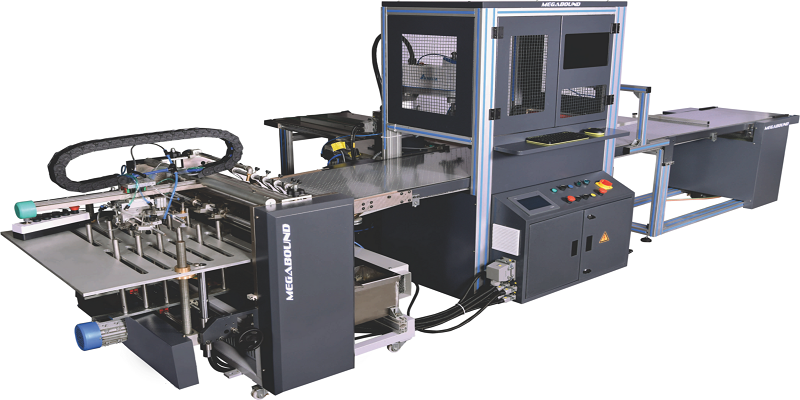

Luxury Boxes are often packaged in rigid cardboard boxes. There is a wide variety of machinery available to make these boxes, from simple hand-held machines to sophisticated automated systems.

Some of the simpler machines are powered by hand, using simple levers and pulleys to move the paper or plastic box around. These machines can be operated by one person, and are suited for small batches of boxes.

More advanced machines use computerized controls to move the box around automatically. These systems are more accurate and can handle larger quantities of boxes with ease. They can also be programmed to produce specific types of boxes, such as square or rectangular shapes.

Regardless of the type of machine used, all luxury boxed require careful assembly and careful handling in order to prevent damage to the box or its contents.

Types Of Machinery

There are many different types of machinery that can be used to produce luxury wrapped rigid cardboard boxes. The most common type of machinery used for this purpose is a roll-forming machine. This type of machine is used to create the desired shape and size of the box. Other types of machines that can be used for this purpose include die cutting machines, embossing machines, and punching machines.

Die cutting machines are often used to create the shapes and details on the boxes. They come in a variety of shapes and sizes and can be used to cut out multiple parts at once. Embossing machines are typically used to add decorative details to the boxes.

They come in a variety of sizes and shapes and can be used to create raised or sunken features on the box surface. Punching machines are commonly used to create openings in the boxes. They come in a variety of shapes and sizes and can be used to punch out numerous holes in the box surface.

Advantages And Disadvantages Of Machinery

There are many advantages and disadvantages to using machinery for rigid boxes. The main advantage is that it can be done quickly and efficiently, which is useful when there is a high demand for the boxes. Additionally, the machines can be customized to produce the desired box shape and size. The disadvantage of using machinery is that it can be expensive, and it may not produce the perfect box every time.

Conclusion

Looking for a machinery that can efficiently wrap luxury wrapped rigid cardboard boxes? Then you should consider investing in a Wrapping Machine from our extensive range. These machines are designed to pack delicate and large objects securely, quickly and without any damage. Browse through our selection today and find the perfect machine for your needs!